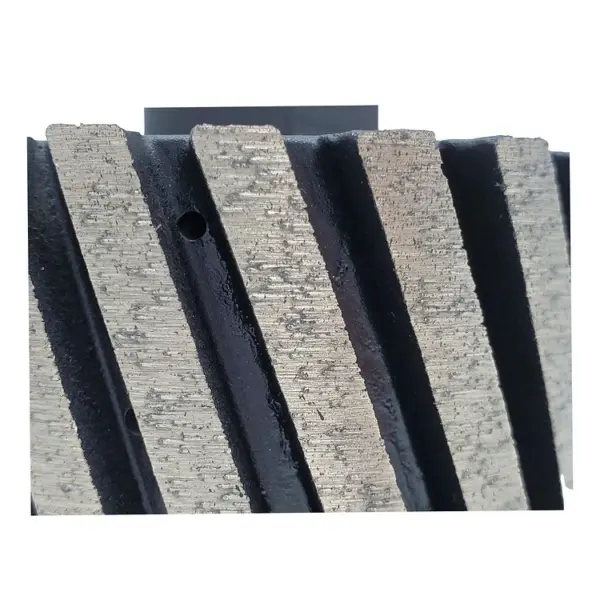

High-Speed Grinding and Shaping for Stone Fabrication!

Non-Resin, Diamond Drum Wheels, Made With Professional Quality Diamonds, Deliver the Fastest Grinding, Shaping and Honing Performance on Marble, Granite, Quartz, Nano-Glass, Dekton & Quartzite Stone. Available in 1 in, 2 in, 3 in and 4 in x 1-3/8″ Length x 5/8-11 Thread. Stone Tool Shop, Zero Tolerance Diamond Drum Wheels Provide the Most Efficient Grinding Utility for Sink Bowls Edge Profiles.

Non-Resin Design, Provides Maximum Stock Removal Rates for Increased Production! Machine Balanced to Eliminate Vibration at High RPMs. Made in South Korea.

- Non-Resin

- 1 in, 2 in, 3 in x 4 in x 1-5/8″ Length

- 5/8″-Thread

- 30/40# Coarse

- 50/60# Medium

- Wet & Dry Operation

- 8,000 Max RPM

Key Features and Benefits

1. Non-Resin Design:

Provides aggressive material removal for faster grinding and shaping, reducing project time.

2. Vacuum Brazed Diamond Technology:

Ensures durability and consistent performance, even on hard and dense materials.

3. Wide Material Compatibility:

Excels on a variety of stones, including:

- Marble

- Granite

- Quartz and Quartzite

- Nano-Glass

- Dekton

4. Precision and Stability:

Machine-balanced construction minimizes vibration, ensuring smoother and more accurate results.

5. Versatile Operation:

Designed for both wet and dry use, adapting to various project conditions and tools.

6. Multiple Size Options:

Available in 2″, 3″, and 4″ diameters to suit different project requirements.

Specifications

- Sizes Available: 1 inch, 2 inch, 3 inch, 4 inch x 1-5/8″ length

- Grit: 30/40# Coarse, 50#/60# Medium

- Thread Type: 5/8-11

- Operation Modes: Wet and Dry

- Maximum Speed: 10,000 RPM

- Material Compatibility: Marble, Granite, Quartz, Nano-Glass, Dekton, Quartzite

Applications

The Zero Tolerance Diamond Drum Wheels | Non-Resin are ideal for:

- Edge Shaping: Achieve precise edges for countertops, sinks, and decorative stonework.

- Fast Stock Removal: Quickly grind and shape stone slabs for increased production efficiency.

- Sink Cut-Outs: Smooth and refine sink openings with ease.

- Custom Fabrication: Perfect for detailed stone projects requiring aggressive grinding and shaping.

Why Choose These Drum Wheels?

1. Maximum Efficiency:

Non-resin design delivers aggressive stock removal, speeding up fabrication time.

2. Durable and Reliable:

Vacuum brazed diamonds provide long-lasting performance for heavy-duty applications.

3. Precision and Stability:

Machine-balanced design ensures minimal vibration for smooth, professional results.

4. Versatile and Convenient:

Works with both wet and dry systems, offering flexibility for various project environments.

5. Trusted Quality:

Made in South Korea, these drum wheels are crafted to meet the highest industry standards.

How to Use

- Attach to Tool: Secure the drum wheel to your grinder or polishing tool using the 5/8-11 thread.

- Select Operation Mode: Use wet or dry operation depending on project needs.

- Adjust Speed: Set your tool to a maximum of 10,000 RPM for optimal performance.

- Begin Grinding: Guide the drum wheel along the stone surface for aggressive material removal and precise shaping.

- Maintain the Tool: Clean after each use to prolong lifespan and maintain performance.

Who Is This Product For?

- Stone Fabricators: Ideal for professional countertop and sink cut-out projects.

- Contractors and Installers: Suitable for on-site stone grinding and shaping tasks.

- Restoration Specialists: Great for reshaping and refinishing stone surfaces.

Order Your Zero Tolerance Diamond Drum Wheels Today

Upgrade your stone fabrication capabilities with the Zero Tolerance Diamond Drum Wheels | Non-Resin, designed for maximum efficiency, durability, and precision. Whether you’re grinding, shaping, or honing, these drum wheels deliver professional-grade performance for natural and engineered stone.

With options for1 inch, 2 inch, 3 inch, 4 inch x 1-5/8″ length, compatibility with wet and dry operations, and a non-resin design for fast material removal, these tools are perfect for your most demanding projects.

Order now and experience the difference in quality and performance!